Drilling

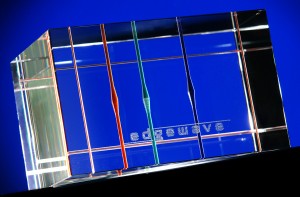

Fig. left illustrates innovative application of the InnoSlab-laser – precision glass drilling, where highly precise hollow structures are created in the glass with shapes, not being machine able with conventional mechanical methods. By the patented technology the laser beam is applied from the back of the work piece and is focused to the opposite inner surface. In contrast to the sub-surface engraving and cutting process the evaporated glass material is able to freely flow away from the processing zone and by appropriate steering of the beam very precise and reproducible holes with any cross-sections can be produced in the glass. The discussed process has a couple of fundamental advantages:

the process is highly precise and reproducible, as the out-streaming material vapour does not interact with the laser beam, what would result in a severe quality reduction due to the occurring plasma processes;

the process is highly precise and reproducible, as the out-streaming material vapour does not interact with the laser beam, what would result in a severe quality reduction due to the occurring plasma processes;- the depth of the hole or the aspect ratio (hole depth in relation to hole diameter) respectively is scalable almost without limit with no loss in accuracy; figure left shows holes with an aspect ratio of infinity;

- holes can be produced with cross-sections which are changing along the hole depth: the hole in figure left has a precise conical broadening in the middle; such boreholes can not be created with any other method;

- due to the illustrated layer-wise removal process it is possible to create nearly any three-dimensional structure in glass and glass-like materials.

Precision drilling in glass: boreholes can be produced; having a depth-dependant cross-section (the holes in the picture are filled with a coloured liquid to increase visibility

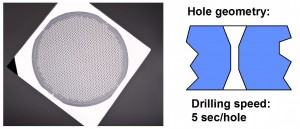

With the InnoSlab-laser operated at frequency of 50 kHz, volume ablation rate more than 1mm³/sec can be  achieved. Figure left shows a glass wafer with more than 1000 holes with tapered cross section. The thickness of the glass wafer is 2mm. The processing time per hole is 5sec. The waist of the holes is 0,5mm.

achieved. Figure left shows a glass wafer with more than 1000 holes with tapered cross section. The thickness of the glass wafer is 2mm. The processing time per hole is 5sec. The waist of the holes is 0,5mm.

Cutting

Full body cutting of glass sheet for touch screen display and 3D cutting of glass  condensers of for concentrating solar can be realized using the layer by layer ablation process. Examples are shown in figure left. In case of touch screen display the thickness of the glass is 0.7mm. The maximum cutting speed achieved amounts 10mm/sec.

condensers of for concentrating solar can be realized using the layer by layer ablation process. Examples are shown in figure left. In case of touch screen display the thickness of the glass is 0.7mm. The maximum cutting speed achieved amounts 10mm/sec.